10 Reasons Why Best Quick Die Change System Boosts Your Production Efficiency by 30 Percent

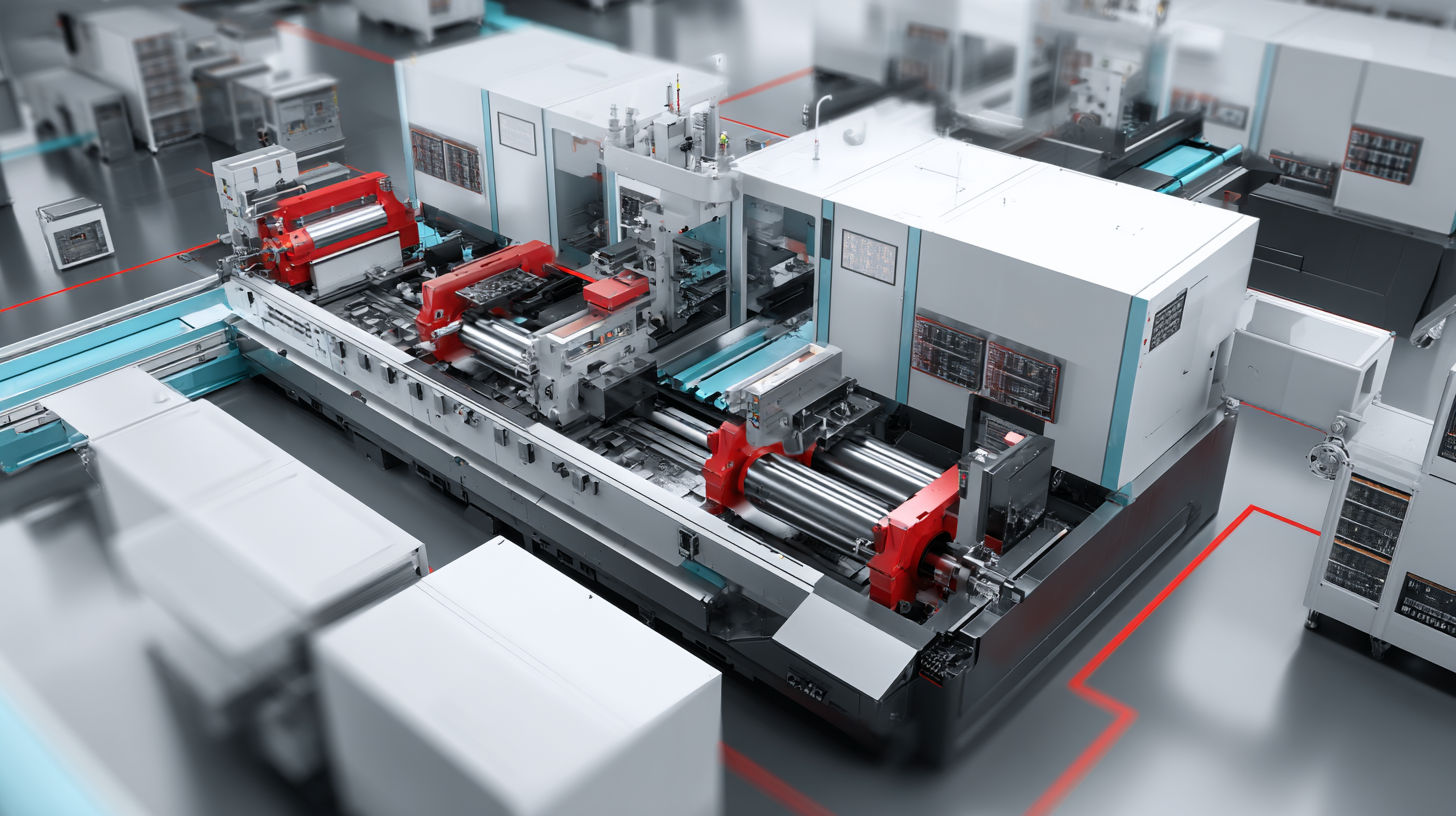

In the highly competitive manufacturing landscape, efficient production processes are paramount for success. A recent report from the Society of Manufacturing Engineers illustrates that companies adopting advanced production methodologies can increase their operational efficiency by up to 30%. One such methodology gaining traction is the Quick Die Change System (QDCS), which significantly reduces downtime associated with tool changes. With traditional die change methods sometimes requiring hours, QDCS streamlines this process to mere minutes, thus facilitating shorter production runs and greater flexibility in responding to market demands. As industries strive for agility and responsiveness, incorporating a Quick Die Change System becomes not just a strategy for improvement, but a necessity for maintaining a competitive edge and maximizing production throughput.

In the highly competitive manufacturing landscape, efficient production processes are paramount for success. A recent report from the Society of Manufacturing Engineers illustrates that companies adopting advanced production methodologies can increase their operational efficiency by up to 30%. One such methodology gaining traction is the Quick Die Change System (QDCS), which significantly reduces downtime associated with tool changes. With traditional die change methods sometimes requiring hours, QDCS streamlines this process to mere minutes, thus facilitating shorter production runs and greater flexibility in responding to market demands. As industries strive for agility and responsiveness, incorporating a Quick Die Change System becomes not just a strategy for improvement, but a necessity for maintaining a competitive edge and maximizing production throughput.

Top Industries Leveraging Quick Die Change Systems for Enhanced Efficiency

In today’s competitive manufacturing landscape, industries are increasingly turning to Quick Die Change (QDC) systems to enhance efficiency and productivity. According to a report published by the Manufacturing Institute, manufacturers that have implemented QDC systems have reported up to a 30% increase in production efficiency. This significant boost is largely due to the reduced downtime associated with traditional die change processes, allowing for quicker transitions between different production runs.

Industries such as automotive, aerospace, and packaging are leading the charge in adopting QDC technologies. For example, the automotive sector, which often deals with high-volume production and diverse product lines, has found that integrating QDC systems can cut die change times from several hours to just minutes. A study by the Society of Manufacturing Engineers noted that companies implementing QDC saw up to a 50% reduction in changeover time, translating directly into cost savings and improved operational throughput. As these sectors continue to innovate and streamline operations, the role of Quick Die Change systems will only grow more critical in maximizing efficiency and maintaining a competitive edge.

Key Performance Metrics: A 30% Efficiency Boost Through Improved Changeovers

In today’s fast-paced manufacturing environment, enhancing production efficiency is crucial for staying competitive. One of the most impactful ways to achieve this is through adopting the best quick die change systems. By streamlining the changeover process, companies can realize a substantial efficiency boost—often estimated around 30%. This improvement is rooted in key performance metrics which highlight how effective changeovers directly correlate with production speed.

Improved changeover processes minimize downtime, ensuring that machinery is operational for longer periods and reducing the lag that often accompanies traditional methods. Metrics such as changeover time, machine availability, and overall equipment effectiveness (OEE) become pivotal in assessing the success of quick die change systems. Not only do these systems decrease the time needed for adjustments, but they also enhance worker productivity and morale by fostering a smoother workflow. The result is a significant uptick in production output, making a compelling case for manufacturers to invest in advanced changeover technologies.

The Role of Reduced Downtime in Manufacturing Profitability

In the fast-paced world of manufacturing, minimizing downtime is crucial for maximizing profitability. Reduced downtime directly correlates with the ability to maintain consistent production schedules, ultimately leading to enhanced output and better resource allocation. One of the most effective strategies to achieve this is through implementing a best quick die change system. By streamlining the process of switching out dies, manufacturers can significantly cut the time spent on setup, resulting in more time devoted to productive operations.

Additionally, the reduction in downtime not only boosts production efficiency but also fosters a more agile manufacturing environment. When downtime is minimized, companies can respond to market demands swiftly, adapting production lines to changes in order volume or product specifications. This agility not only meets customer needs but also secures a competitive edge. As a result, investing in superior quick die change systems is not just about speeding up production; it is about creating a robust framework that enhances overall profitability while ensuring that businesses stay relevant in a dynamic market landscape.

How Quick Die Change Practices Align with Lean Manufacturing Principles

Quick die change (QDC) practices have increasingly proven their alignment with lean manufacturing principles, significantly enhancing production efficiency. By minimizing downtime associated with tooling and die changes, such practices adhere to the core lean philosophy of waste reduction and continuous improvement. The Single Minute Exchange of Die (SMED) method, a critical innovation in the realm of manufacturing, showcases how internal and external setup tasks can be streamlined to achieve remarkable time savings. This transformation not only allows manufacturers to respond swiftly to changing demands but also promotes a culture of agility and responsiveness.

As swift and efficient die change operations become more integral to production strategies, shops are re-evaluating their QDC equipment and methodologies. The evolution of quick die change systems is reflective of broader trends in lean manufacturing, aiming to create a more flexible and efficient workplace. The incorporation of modern techniques not only reduces the time needed for die changes but also fosters a more engaged workforce, capable of making rapid, informed decisions. By embedding quick change practices into their processes, manufacturers can achieve substantial gains in productivity while also enhancing their overall operational resilience.

10 Reasons Why Best Quick Die Change System Boosts Your Production Efficiency by 30 Percent

| Reason | Impact on Efficiency | Lean Manufacturing Principle | Examples |

|---|---|---|---|

| Reduced Setup Time | 20% Increase | Value Stream Mapping | Quick tool swaps |

| Enhanced Worker Efficiency | 15% Increase | Respect for People | Worker training on systems |

| Fewer Errors During Changeovers | 10% Increase | Continuous Improvement | Standardized procedures |

| Optimized Inventory Management | 5% Inventory Reduction | Just-In-Time | Lean stock levels |

| Improved Equipment Uptime | 25% Increase | Eliminate Waste | Regular maintenance |

| Increased Flexibility in Production | 30% Flexibility Boost | Adaptability | Quickly switch products |

| Shortened Lead Times | 20% Reduction | Flow Efficiency | Less wait time |

| Enhanced Collaboration Among Teams | 15% Improvement | Teamwork | Cross-training |

| Knowledge Sharing | 10% Knowledge Increase | Empowerment | Best practice meetings |

| Scalability for Future Projects | Future-Proofing | Scalability | Modular setups |

Case Studies: Companies Achieving 30% Production Increases with Fast Change Systems

In today’s competitive manufacturing landscape, companies are increasingly turning to quick die change systems to enhance production efficiency. Case studies reveal that organizations adopting these systems have witnessed production increases of up to 30%. For instance, a leading automotive parts manufacturer implemented a quick die change system and reduced setup times by nearly 50%. This not only allowed for more flexible production scheduling but also significantly decreased downtime, enabling them to respond swiftly to customer demands.

Another compelling example comes from a prominent electronics assembly firm that integrated fast change systems into their operations. By streamlining their changeover processes, they were able to minimize interruptions between production runs. As a result, the company reported a remarkable 30% boost in overall productivity within just a few months. These success stories underscore the transformative impact of quick die change systems, illustrating how they can revolutionize operational capabilities and drive substantial gains in manufacturing efficiency.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी