Exploring Best Quick Mold Change System Solutions for Automotive Manufacturing Applications

The automotive manufacturing industry is under increasing pressure to enhance production efficiency and reduce lead times, prompting a significant shift towards innovative solutions such as Quick Mold Change Systems. According to a recent study by the International Automotive Manufacturing Research Association, companies implementing Quick Mold Change Systems have reported a reduction in downtime by up to 50%, translating to substantial improvements in productivity and output. As the demand for customized vehicle components rises, the ability to swiftly switch molds in production environments has become crucial.

The automotive manufacturing industry is under increasing pressure to enhance production efficiency and reduce lead times, prompting a significant shift towards innovative solutions such as Quick Mold Change Systems. According to a recent study by the International Automotive Manufacturing Research Association, companies implementing Quick Mold Change Systems have reported a reduction in downtime by up to 50%, translating to substantial improvements in productivity and output. As the demand for customized vehicle components rises, the ability to swiftly switch molds in production environments has become crucial.

Additionally, the global automotive market is projected to witness a compound annual growth rate (CAGR) of 4.5% through 2026, emphasizing the need for systems that can adapt to changing manufacturing requirements. In this blog, we will explore the best Quick Mold Change System solutions tailored for automotive applications, examining how these technologies can support manufacturers in meeting their operational goals and maintaining a competitive advantage.

Benefits of Quick Mold Change Systems in Automotive Manufacturing

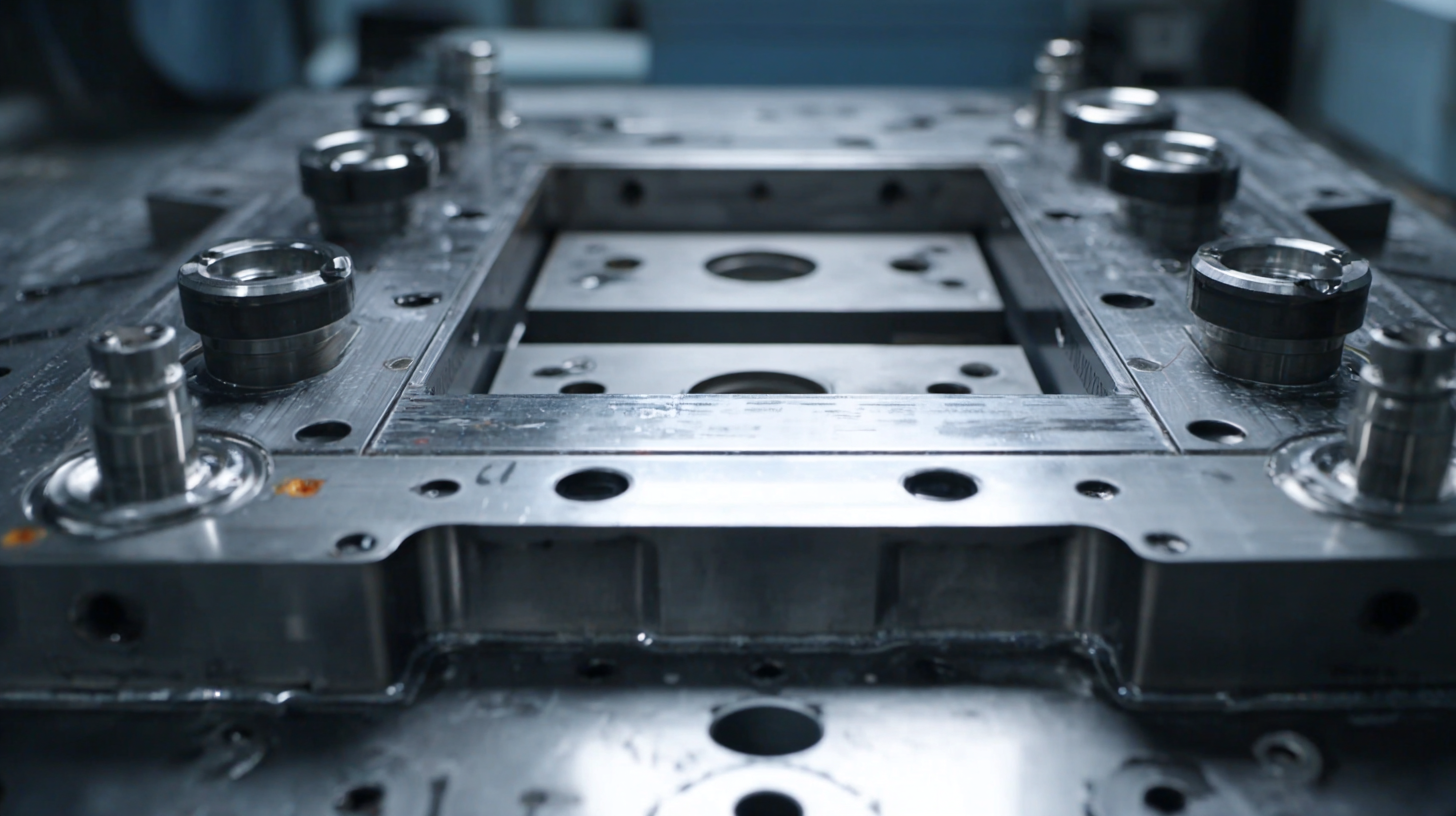

Quick Mold Change Systems (QMC) play a pivotal role in enhancing efficiency and productivity within the automotive manufacturing sector. By significantly reducing downtime during mold changes, these systems allow for a seamless transition between different production runs, which is especially crucial in an industry that demands rapid adaptability to shifting consumer preferences. According to recent industry insights, the global small rotary damper market—integral for QMC systems—is projected to reach approximately USD 1.5 billion by 2024, illustrating the growing investment in technologies that support quicker mold changes.

Moreover, the adoption of additive manufacturing technologies is revolutionizing mold modification processes. Direct metal deposition (DMD) has been shown to enhance production speeds by 250-330% when compared to traditional manual methods. This accelerated capability not only streamlines the mold design process but also supports automotive manufacturers in meeting rigorous production schedules. With the 3D printing industry anticipated to surpass USD 40 billion by 2030, it is clear that integrating quick mold change solutions alongside advanced additive manufacturing will be critical for automotive manufacturers aiming for sustainable growth and competitiveness in a rapidly changing market.

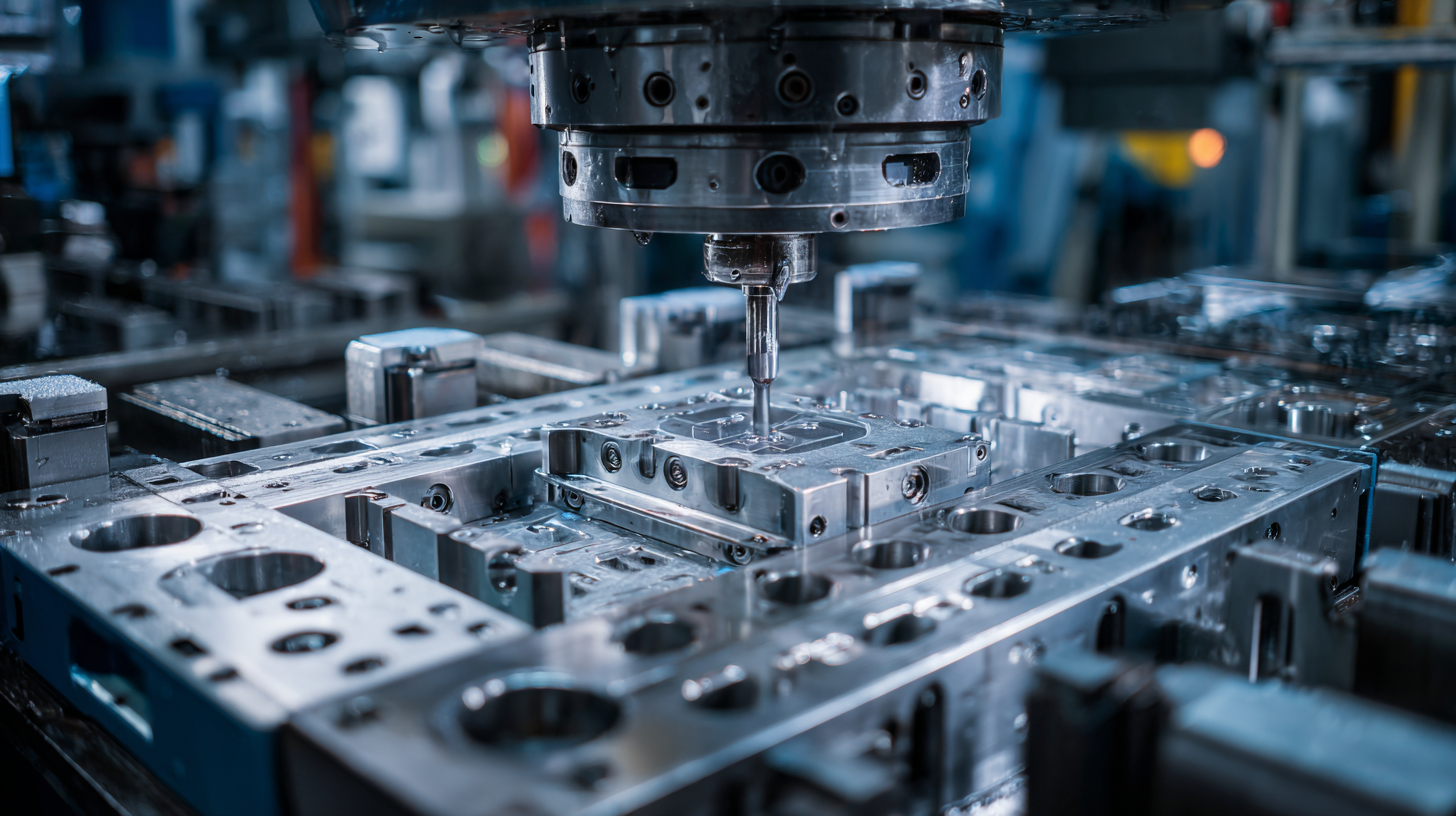

Key Technologies Driving Effective Mold Change Solutions

In the automotive manufacturing sector, the demand for rapid production coupled with flexibility has led to a pivotal shift towards advanced quick mold change systems. Key technologies such as automated mold handling, intelligent sensors, and real-time data analytics are shaping the effectiveness of these systems. According to a recent report by the International Journal of Advanced Manufacturing Technology, manufacturers can achieve a mold change time reduction of up to 70% by implementing these innovations, significantly enhancing overall productivity.

To optimize the mold change process, consider investing in modular mold systems that allow for quick reconfiguration. This flexibility not only expedites the changeover but also minimizes downtime, ultimately contributing to a more agile manufacturing environment. Additionally, incorporating predictive maintenance strategies utilizing IoT technology can preemptively address potential mold issues, further streamlining operations.

Moreover, training employees on the latest technologies and best practices can ensure that workers are equipped to handle the sophisticated systems effectively. Regular workshops and hands-on demonstrations can empower teams to fully leverage quick mold change capabilities, driving efficiency and quality in production processes. Implementing these strategies will not only improve turnaround times but also enhance the overall production quality in automotive manufacturing.

Exploring Best Quick Mold Change System Solutions for Automotive Manufacturing Applications

| Technology | Description | Benefits | Application Type |

|---|---|---|---|

| Automatic Quick Change Systems | Systems that enable rapid mold changes with minimal manual intervention. | Increased efficiency and reduced downtime in production. | Injection Molding |

| Modular Mold Designs | Molds designed in interchangeable parts to simplify changes. | Flexibility in production and cost savings on mold manufacturing. | Die Casting |

| Robotic Mold Handling | Utilization of robots to manage mold changes and movements. | Enhanced safety and precision in handling heavy molds. | Injection Molding |

| Quick Connect Systems | Fast coupling and uncoupling mechanisms for molds. | Reduction in mold change time and improved workflow. | Blow Molding |

| Heat Staking Technology | Incorporates heat to facilitate mold modifications quickly. | Improved accuracy and repeatability in mold alignment. | Thermoforming |

Best Practices for Implementing Quick Mold Change Systems

Implementing a Quick Mold Change (QMC) system in automotive manufacturing can significantly enhance productivity and reduce downtime. Best practices for successfully integrating a QMC system involve thorough planning and training. Before implementation, manufacturers should conduct a comprehensive analysis of their current mold change processes. This includes identifying any bottlenecks, monitoring changeover times, and assessing equipment compatibility. By gathering this data, companies can tailor their QMC strategies to address specific challenges and set realistic goals for improvement.

Once an appropriate QMC system is selected, training the workforce becomes crucial. Operators must be well-versed in the new processes and technologies involved in quick mold changes. Regular training sessions prevent the onset of mistakes during transitions and ensure that all team members understand their roles and responsibilities. Additionally, maintaining clear communication among teams can further streamline the process, allowing for quick adjustments and minimizing delays. Emphasizing collaboration and feedback during the initial phases fosters a culture of continuous improvement, aligning both workforce and technology towards optimized production efficiency.

Case Studies: Successful Mold Change Implementations in the Industry

In the fast-paced world of automotive manufacturing, the ability to efficiently change molds can significantly impact production timelines and costs. Examining successful mold change implementations in the industry reveals valuable strategies that can enhance operational efficiency. For example, one notable case involved a manufacturer that streamlined its mold change process by investing in a quick-change system, resulting in a 30% reduction in downtime. Such advancements not only optimize production flow but also enhance flexibility in responding to market demands.

When considering a quick mold change system, it’s essential to focus on some key tips. First, ensure that the system is compatible with existing equipment and workflows to minimize disruption during implementation. Additionally, regular training and support for staff can maximize the benefits of the new system, fostering a culture of continuous improvement. Finally, assess the long-term return on investment by monitoring metrics such as cycle time and overall equipment effectiveness to validate the decision to upgrade.

These case studies demonstrate that the thoughtful integration of technology in mold change processes can yield substantial improvements. By adopting best practices and remaining open to innovation, manufacturers can maintain a competitive edge in an ever-evolving industry.

Future Trends in Quick Mold Change Solutions for Automotive Applications

The automotive manufacturing industry is undergoing a significant transformation, with rapid advancements in quick mold change systems at the forefront. As manufacturers strive for more efficient production lines, future trends reveal a strong shift towards automation and smart technologies. Integrating IoT (Internet of Things) capabilities into quick mold change solutions will allow for real-time monitoring and data analysis, enabling manufacturers to anticipate maintenance needs and minimize downtime. This shift not only enhances productivity but also allows for greater flexibility in responding to market demands.

Moreover, the incorporation of lightweight materials in mold design is set to revolutionize the quick mold change process. As automotive manufacturers seek to improve fuel efficiency and reduce emissions, adopting lighter molds can streamline production while maintaining structural integrity. Additionally, the evolution of modular mold systems is paving the way for easier interchangeability and faster setups. These innovations are essential for manufacturers aiming to optimize their processes and lead in an increasingly competitive automotive landscape. The focus on sustainability and efficiency will likely continue to shape the future of quick mold change solutions, driving the industry towards even greater advancements.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी