In the world of precision engineering, selecting the right tools is essential. One key player is the CNC machine milling machine. These machines have transformed manufacturing processes, offering unmatched precision and efficiency. Companies can create complex parts that meet stringent specifications with ease.

As we approach 2026, the variety of CNC machine milling machines continues to grow. Each option has its strengths and weaknesses. It's crucial to consider not only the features but also how they fit your specific needs. Some machines boast advanced technology, while others focus on affordability.

Choosing the ideal CNC machine milling machine requires careful thought. It’s easy to overlook important details. Features like spindle speed and build quality can significantly impact your operations. Reflecting on your priorities will lead you to the right choice, making all the difference in your engineering projects.

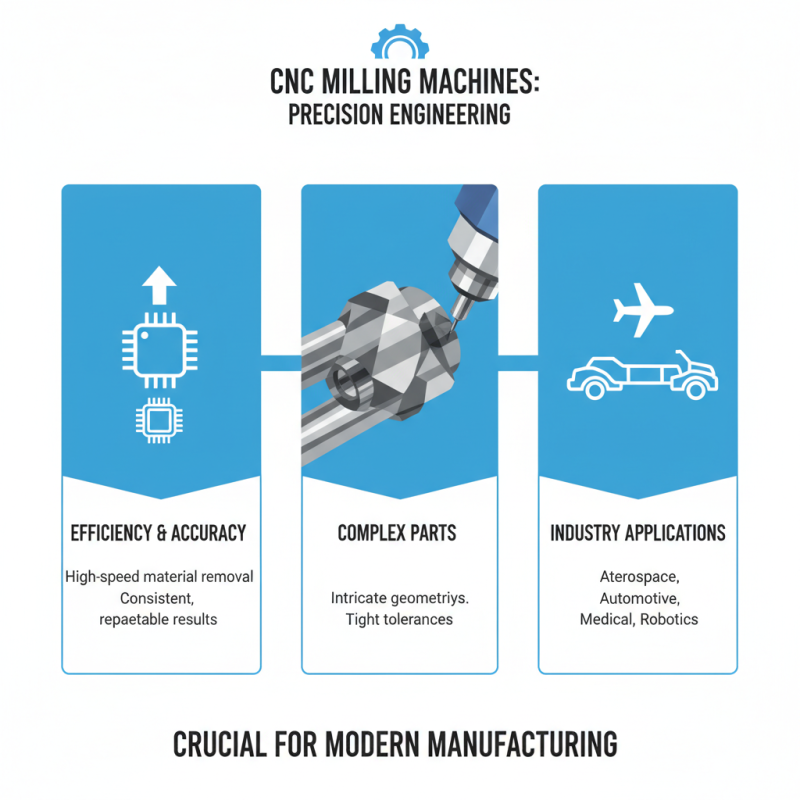

CNC milling machines are essential for precision engineering. They offer highly efficient and accurate machining capabilities. These machines can create complex parts with exact specifications. This precision is crucial across various industries, including aerospace and automotive.

When choosing a CNC milling machine, consider the material you'll work with. Different materials require different cutting tools and speeds. For example, aluminum needs different settings than stainless steel. Additionally, the size of your projects will affect your choice. A compact machine may suffice for small parts, while larger projects need bigger machines.

Tips: Regular maintenance is crucial for optimal performance. Check for wear on tools and machinery. This can prevent costly breakdowns. Also, always keep safety in mind. Proper training ensures everyone uses the machines correctly. Mistakes can lead to injuries or faulty parts. Be cautious and aware at all times.

When selecting a CNC milling machine for precision engineering, several key features must be considered. The machine's rigidity plays a vital role in ensuring accurate cuts. According to industry reports, a stiffer machine can improve overall precision by up to 25%. Material compatibility is also crucial. Understanding the type of materials you will work with can influence your choice significantly.

Speed and feed rates should be evaluated closely. A machine that offers variable speed settings allows greater flexibility which is essential in precision tasks. You should examine the spindle power as well, given that a robust spindle can lead to higher efficiency and longer tool life. It's beneficial to remember that not all machines in the same price range deliver equal performance.

Tip: Start by defining your project's specific requirements. This will guide your selection process and help you avoid overspending on unnecessary features.

Moreover, consider the machine's software compatibility. An intuitive interface can reduce the learning curve, drastically improving productivity. However, many high-end machines still may have a learning curve that might not suit smaller teams. Look for models that balance advanced technology with user-friendly operation.

Tip: Always compare specifications and user reviews to identify the machine that fits your needs the best.

In 2026, CNC milling machines continue to advance in precision engineering. The market offers a range of options that cater to various needs. Some models focus on high-speed machining, ideal for intricate designs. Others prioritize durability, perfect for heavy materials.

Top models often feature advanced automation capabilities. This can enhance accuracy but may lead to over-reliance on technology. Users must balance efficiency with manual oversight. Smaller enterprises might struggle to afford the latest technology. Investing in a CNC milling machine requires careful evaluation.

Precision is vital in engineering, yet the learning curve can be steep. Operators need training to harness the full potential of these machines. Choices can be overwhelming, and not every model will fit all applications. Each should be assessed based on individual project needs. Reflection on past experiences can guide future decisions. Ensuring proper maintenance is as crucial as initial selection.

CNC milling machines have revolutionized precision engineering. They offer a level of accuracy that traditional methods often cannot match. According to industry reports, CNC milling can achieve tolerances as tight as ±0.005 mm. In contrast, traditional milling methods typically maintain a tolerance of ±0.1 mm. This difference can significantly impact the quality of finished products.

Moreover, the automation of CNC machines enhances production speed. Data shows that CNC machining can increase output efficiency by over 50%. Traditional methods require skilled operators to adjust machines throughout the process. This can lead to human error and inconsistencies. In some cases, reliance on manual settings can result in scrap rates climbing to 10% or more. Understanding these challenges is crucial for manufacturers.

Despite these advantages, CNC machines pose their own set of challenges. The initial investment for CNC equipment can be high. Companies must consider training staff to operate and maintain these complex systems. Some may find it difficult to adapt to this technology. A thorough analysis is necessary to decide if CNC milling is a suitable approach for specific engineering needs. Balancing technology capabilities with operational costs remains an ongoing discussion in the engineering community.

The future of CNC milling technology is exciting. Precision engineering is rapidly advancing. New features enhance accuracy and efficiency. Automation plays a crucial role. Machines are becoming smarter and more user-friendly. This allows engineers to focus on design rather than routine tasks.

Tips: Consider investing in machines with adaptive feedback systems. They adjust to changes in real-time for better results. Monitor maintenance needs closely. Neglect can lead to costly downtimes.

Additive manufacturing is a hot trend. Combining milling and 3D printing can optimize production. This hybrid approach offers flexibility and reduces waste. However, challenges exist in material compatibility. Understanding these complexities is vital for success. Experimentation is necessary, but not all results will meet expectations. Embrace the learning process.

© Copyrights Levil Technology Corp 2022