Solutions for Efficient Production with the Best Quick Die Change System

In the fast-paced manufacturing landscape, efficiency and productivity are paramount for staying competitive. One of the most effective ways to streamline production processes is through the implementation of a Quick Die Change System (QDCS). According to a recent report by the Association for Manufacturing Technology, companies that adopted QDCS have reported an average reduction of up to 50% in changeover times, significantly enhancing overall operational efficiency. As production demands continue to increase, embracing strategies that leverage quick die change not only meets market needs but also reduces downtime and minimizes labor costs. This blog will explore the top strategies for optimizing your production environment with the best practices in Quick Die Change Systems, ensuring that your operations are both efficient and cost-effective.

Benefits of Implementing Quick Die Change Systems in Manufacturing

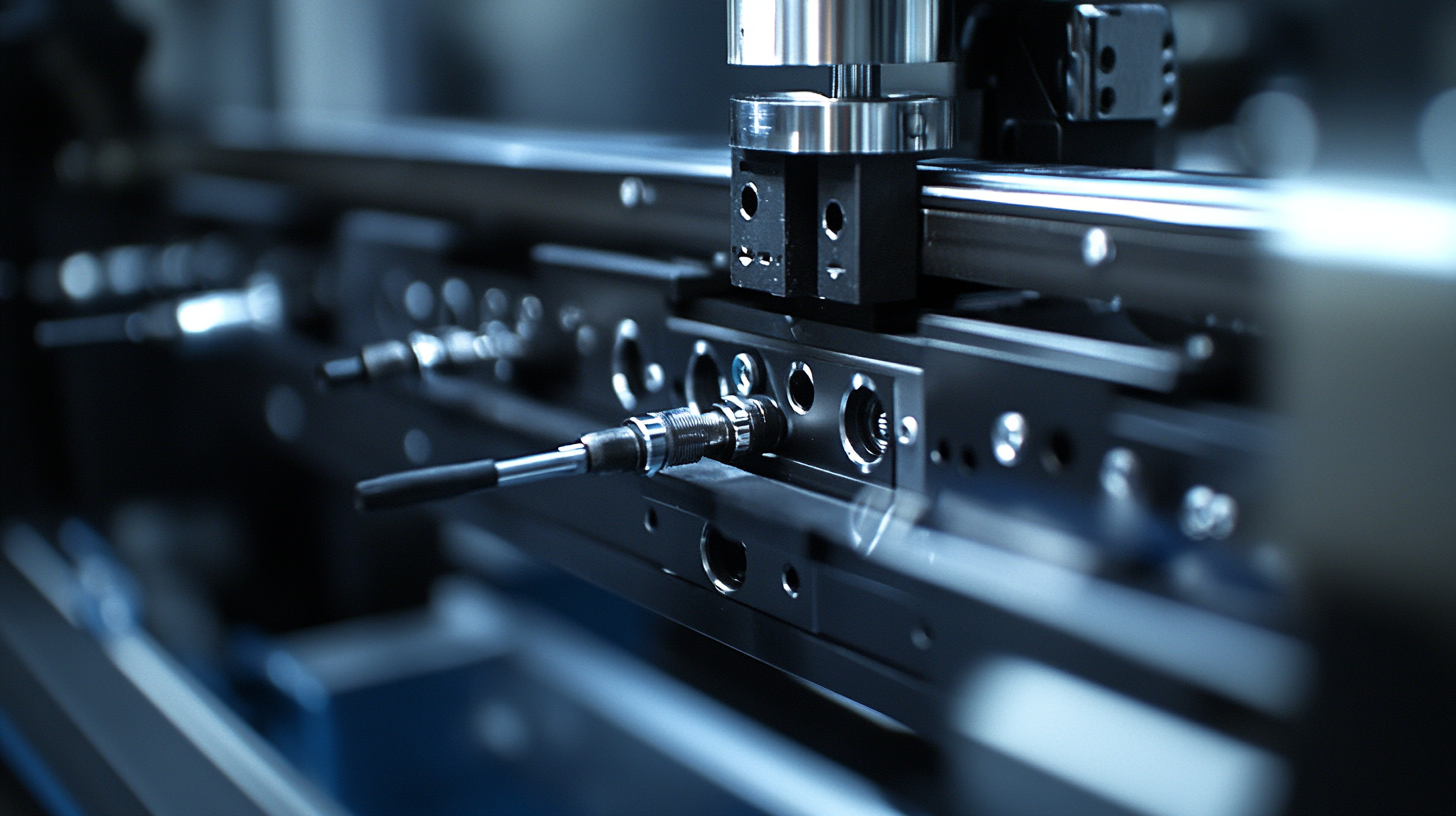

The implementation of Quick Die Change (QDC) systems in manufacturing has proven to be a game-changer for enhancing operational efficiency. By utilizing advanced tools such as T-tables, die carts, and rolling bolster systems, manufacturers can significantly reduce downtime associated with die changes. This transformation not only streamlines the production process but also maximizes equipment uptime, allowing firms to meet increasing market demands more effectively.

The implementation of Quick Die Change (QDC) systems in manufacturing has proven to be a game-changer for enhancing operational efficiency. By utilizing advanced tools such as T-tables, die carts, and rolling bolster systems, manufacturers can significantly reduce downtime associated with die changes. This transformation not only streamlines the production process but also maximizes equipment uptime, allowing firms to meet increasing market demands more effectively.

As the manufacturing sector evolves, the integration of QDC systems aligns with broader trends such as Industry 4.0, which emphasizes automation and data exchange. With innovations like magnetic clamping systems that require no retooling, manufacturers can further optimize their operations. This adaptability is essential in a rapidly changing economic landscape where agility and efficiency are paramount to staying competitive. The focus on targeted technological investments is not just about enhancing productivity; it's also about fostering sustainability in a fragmented market by reducing waste and enhancing the lifecycle of manufacturing tools.

Key Features to Look for in the Best Quick Die Change Systems

In today’s fast-paced manufacturing environment, selecting the right quick die change (QDC) system is crucial for maximizing productivity and efficiency. Key features to look for include adaptability, speed, and ease of use. According to a report from the Society of Manufacturing Engineers, the optimal QDC systems can reduce changeover times by up to 50%, significantly enhancing production flow and minimizing downtime. This adaptability is essential for manufacturers who require flexibility in their operations to accommodate diverse product runs.

Another vital aspect is the integration of automated solutions within QDC systems. Research from the International Journal of Advanced Manufacturing Technology indicates that QDC systems equipped with automation technology can lead to a 30% reduction in labor costs associated with changeovers. Features such as intuitive controls and real-time monitoring capabilities further enhance operational efficiency. Overall, investing in a high-quality quick die change system not only streamlines the production process but also plays a critical role in maintaining competitive advantage in the manufacturing sector.

Solutions for Efficient Production with the Best Quick Die Change System - Key Features to Look for in the Best Quick Die Change Systems

| Feature | Description | Benefits |

|---|---|---|

| Automated Alignment | System automatically aligns dies during changes. | Reduces setup time and increases accuracy. |

| Quick Release Mechanism | Allows rapid swapping of dies with minimal manual intervention. | Speeds up production cycles significantly. |

| Durability and Robustness | Constructed from high-strength materials to withstand stress. | Ensures longevity and reduces the risk of failures. |

| Modular Design | Flexibility to adapt to different tools and machines. | Enhances versatility and efficiency in production. |

| Safety Features | Equipped with sensors and emergency stop functions. | Minimizes risk of accidents during operations. |

| Maintenance Alerts | Integrated alerts for maintenance needs and system checks. | Improves uptime and equipment reliability. |

Case Studies: Successful Quick Die Change Implementation in Chinese Factories

Quick Die Change (QDC) systems have revolutionized production efficiency in various industries, particularly in Chinese factories where the demand for rapid turnover is essential. Case studies show that the implementation of QDC has led to significant reductions in downtime, allowing manufacturers to adapt to market demands more swiftly. For instance, one factory reported a 30% increase in production capacity after adopting a streamlined QDC process, demonstrating its effectiveness in minimizing production interruptions.

To achieve similar results, factories should consider the following tips: first, invest in proper training for staff to ensure they are well-versed in the QDC tools and processes. Well-trained employees can significantly decrease changeover times as they work with greater confidence and efficiency.

Second, regular maintenance of die equipment is crucial. Keeping tools in top condition helps prevent unexpected breakdowns and prolongs equipment life, directly contributing to smoother and faster transitions between production runs.

Another essential tip is the use of standardized procedures. Documenting and implementing consistent changeover practices can reduce variability and confusion during the QDC process. Factories that adopt a systematic approach often find it easier to identify areas for improvement, leading to ongoing enhancements in efficiency and productivity.

Comparative Analysis: Quick Die Change vs. Traditional Die Change Methods

In the landscape of modern manufacturing, the Quick Die Change (QDC) system emerges as a pivotal advancement over traditional die change methods. This technique, characterized by its Single Minute Exchange of Dies (SMED) approach, significantly reduces the downtime associated with changeovers. Instead of lengthy interruptions that can disrupt production schedules, QDC offers a streamlined process, enabling manufacturers to quickly switch out dies with minimal manual intervention. This innovation not only enhances productivity but also translates into substantial cost savings, making it an appealing solution for manufacturers aiming to maintain competitive advantage.

Comparatively, traditional die change methods often involve labor-intensive processes that can take hours, if not days, to complete. This not only hampers efficiency but also increases the likelihood of errors and inconsistencies during production. The advantages of Quick Die Change become particularly evident in high-demand industries where flexibility and speed are crucial. As companies strive to meet the evolving needs of the market, adapting to the benefits of QDC can position them favorably in an increasingly tech-driven environment, reinforcing the necessity for innovative approaches in manufacturing.

Future Trends in Quick Die Change Technologies for Global Manufacturing

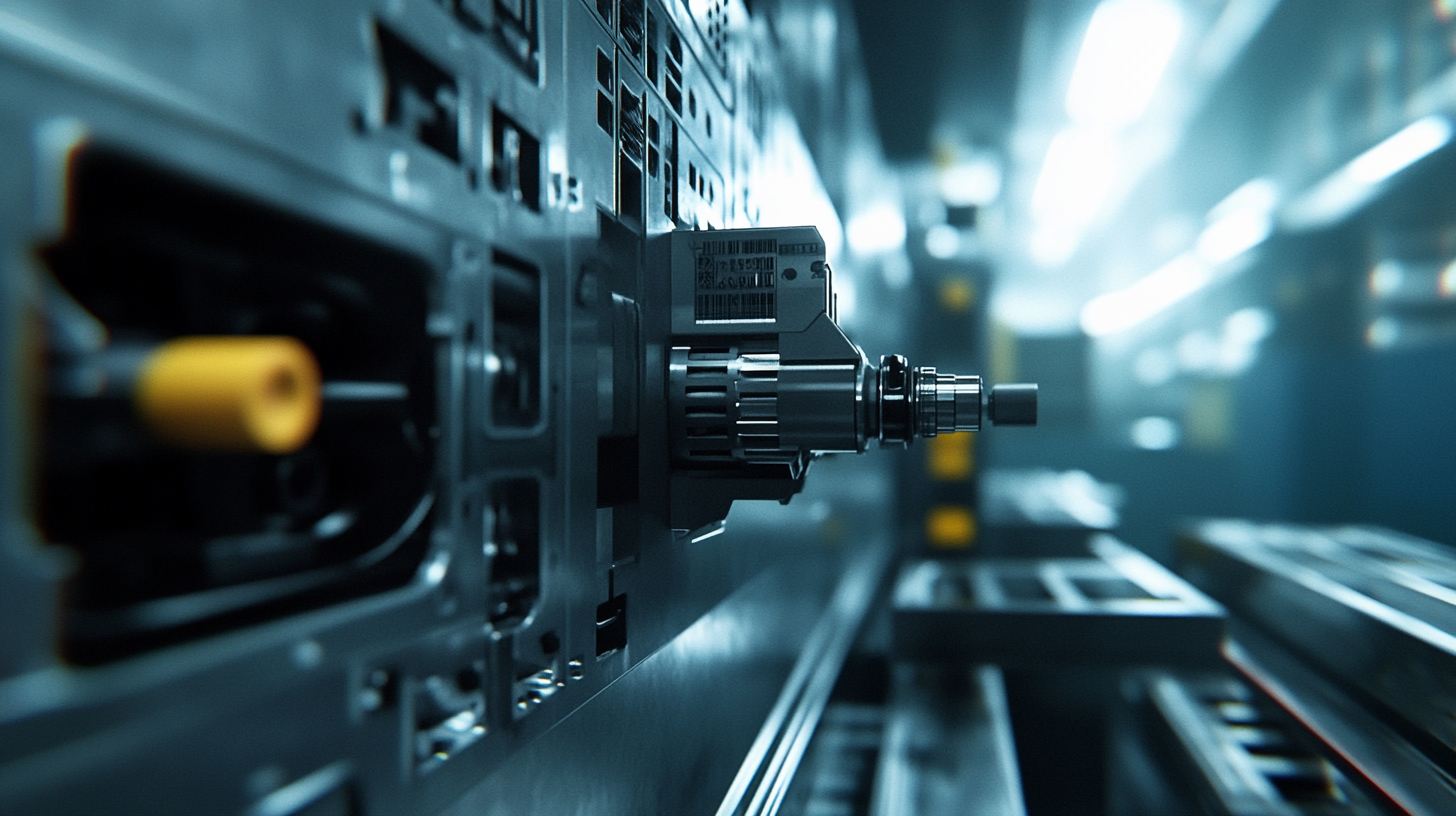

The landscape of global manufacturing is evolving rapidly, with quick die change (QDC) technologies at the forefront of this transformation. As industries strive for greater efficiency and reduced downtime, the future of QDC systems is likely to integrate advanced automation and IoT capabilities. These innovations will not only streamline the die change process but also enhance real-time monitoring and predictive maintenance, ensuring that manufacturers can anticipate issues before they arise. By leveraging data analytics, organizations will be able to make more informed decisions, optimizing their production schedules and resource allocation.

Furthermore, sustainable manufacturing practices are influencing the development of QDC technologies. Future systems will likely prioritize eco-friendly materials and energy-efficient processes to minimize their environmental footprint. The push for modular designs will make it easier for manufacturers to adapt their setups to different production requirements swiftly. As the demand for customization and rapid turnaround times increases, manufacturers that adopt these emerging QDC technologies will position themselves to lead in a competitive global marketplace, showcasing flexibility and innovation.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी