In the world of precision machining, leveraging a 4 axis CNC machine can significantly enhance productivity. According to John Smith, a renowned expert in CNC technology, "Mastering a 4 axis CNC machine can revolutionize your workflow." This statement underscores the importance of efficiency in today's competitive market.

Utilizing a 4 axis CNC machine allows for complex shapes and intricate designs. Operators can achieve results that would be impossible with traditional machinery. However, many companies struggle to fully harness this potential. They often overlook critical strategies that could enhance efficiency. This creates missed opportunities for growth and improvement.

Investing in proper training and maintenance can transform operations. Without it, even the best machinery can underperform. It's essential to engage in continual learning and adaptation. The journey of mastering a 4 axis CNC machine includes both successes and challenges. Embracing this reality can lead to significant advancements in machining processes.

4 axis CNC machines offer unique capabilities that enhance production efficiency. They provide rotational movement along an axis, allowing for complex geometries and intricate designs. According to recent industry reports, these machines can significantly reduce machining time by up to 30%. This increase in efficiency is crucial for industries that require precision and speed.

Understanding 4 axis CNC machines is essential for maximizing their potential. They typically consist of three linear axes and one rotary axis. This configuration allows for multi-sided machining, reducing the need for re-fixturing. Some studies show that businesses using these machines experience a 25% reduction in labor costs. However, operator training remains a challenge. New users may struggle with programming, leading to errors.

Delving deeper, many users face difficulties in fully utilizing these machines. The intricacies of setup can lead to delays. Data indicates that about 40% of teams report issues with initial programming. It’s important to reflect on these obstacles. Benchmarking against industry standards can provide a clearer pathway to overcoming these hurdles and improving productivity.

Maximizing efficiency in CNC operations starts with optimizing the setup process. Ensure that materials are readily available near the machine. This reduces the time spent searching for tools and components. Organizing tools in a designated area can help streamline workflow. Remember, an organized workspace leads to focused work.

Another essential strategy is proper programming. Streamline your code to minimize finishing time without sacrificing quality. This involves avoiding unnecessary tool changes and ensuring that paths are efficient. However, take time to review your programs. Overlooking small errors can cost valuable time and resources later. Additionally, consider the use of simulation software to catch potential issues before running the actual job.

Regular maintenance of the CNC machine is crucial. A well-maintained machine operates smoothly, reducing downtime. However, it's also important to balance maintenance with production needs. Too frequent checks might disrupt workflow. Reflect on maintaining a schedule that works for your operation without causing interruptions. Small adjustments to these strategies can yield significant improvements over time.

| Tip | Description | Expected Outcome | Implementation Time |

|---|---|---|---|

| Optimize Tool Selection | Choose the right tools for specific materials to enhance cutting efficiency. | Reduced machining time and improved surface finish. | 1-2 days |

| Regular Maintenance | Conduct routine checks and maintenance on CNC machines to prevent downtime. | Increased machine longevity and reliability. | Ongoing |

| Implement Efficient Workflows | Streamline the setup and workflow processes to reduce idle time. | Enhanced overall production speed and efficiency. | 1 week |

| Invest in Software Upgrades | Use updated CNC software for better control and programming capabilities. | Improved accuracy and easier programming of complex parts. | 2-4 weeks |

Choosing the right tools is essential for maximizing the performance of a 4-axis CNC machine. Different materials require specific tools to ensure precision and efficiency. For instance, when machining hard metals, using a carbide tool can significantly enhance the cutting process. In contrast, softer materials like plastics benefit from high-speed steel tools. Not every tool is ideal for every job. Sometimes, users might be tempted to use what they have on hand instead of the right tool.

The geometry of the cutting tool plays a crucial role as well. A tool with an improper angle can lead to poor quality and increased wear. Operators must consider factors such as rake angle and clearance. Adjusting these angles based on the material can lead to better finishes and extended tool life. However, changing tool settings can be time-consuming. It’s easy to overlook these details when working under tight deadlines.

Regular evaluation of tool performance is vital. Users should track the results of each tool used. This will help in identifying which combinations yield the best outcomes. Occasionally, a tool might perform well on paper but fails in practice. Documenting such instances allows for continuous improvement. Re-evaluating choices leads to better decision-making in future projects.

When optimizing programming techniques for a 4 Axis CNC machine, precision and efficiency are key. A report by the National Institute of Standards and Technology highlights that optimizing programming can improve machining speeds by as much as 30%. This means selecting the right tool paths and minimizing rapid movements can make a significant impact on overall productivity.

Effective code management is another vital aspect. Poorly written code can lead to machine errors or downtime. According to industry experts, around 20% of production time may be lost due to incorrect programming. It’s essential to review G-code thoroughly for errors. Small mistakes can lead to substantial delays and wasted materials.

Furthermore, consider the geometry of the parts being machined. Complex geometries may require specific tool paths for optimal performance. Streamlining these paths can reduce cycle times. Yet, balancing speed and quality is tricky. There may be times when rushing your programming can lead to compromised accuracy. Reflecting on these challenges is crucial for continuous improvement and achieving maximum efficiency.

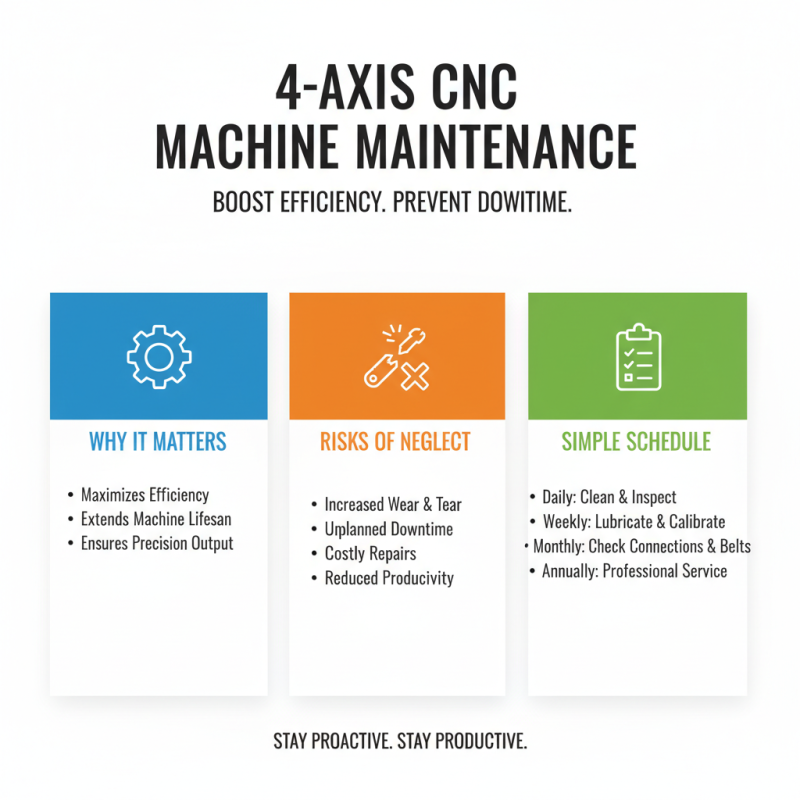

Regular maintenance is crucial for maximizing a 4 axis CNC machine's efficiency and productivity. Neglecting it can lead to wear and tear. This can cause costly downtime. Implementing a simple maintenance schedule can help prevent this.

One effective tip is to regularly check and clean the machine's components. Accumulated dust or debris can hinder performance. Keeping the ball screws and linear guides free of contaminants improves precision. Additionally, lubrication is vital. Properly lubricated parts run smoothly, which can prevent friction issues.

Another important practice is to monitor machine performance regularly. Tracking metrics like run time and accuracy allows you to identify anomalies early. This proactive approach can save time and resources. Gaining insights into machine health helps in making informed decisions. Ultimately, proper maintenance leads to extended machine life and higher productivity. Reflections on maintenance practices can reveal areas for improvement. Consider if your current schedule is effective or if changes are needed to boost efficiency.

© Copyrights Levil Technology Corp 2022