In 2026, the landscape of manufacturing continues to evolve with remarkable advancements in metal printing technology. Dr. Emily Carter, a leading expert in additive manufacturing, states, "Metal printing unlocks new design possibilities that were once unimaginable." This technology has revolutionized industries like aerospace, automotive, and healthcare, allowing for lightweight structures and customized components.

Metal printing enables intricate designs that traditional methods cannot achieve. The process reduces material waste significantly. For instance, parts can be created layer by layer, which minimizes excess. However, the general perception can sometimes overlook the challenges involved. The cost of metal printing remains high for many businesses.

Moreover, the learning curve is steep. Companies must invest time and resources to train their teams. Not every part is suitable for metal printing. A careful analysis of the application is essential. Overall, while metal printing promises numerous benefits, a nuanced understanding of its limitations is crucial for effective implementation.

Metal printing technology has made significant advancements in 2026. This year, new materials have been introduced that allow for improved strength and durability. The applications have expanded to various industries, including aerospace and healthcare. Manufacturing processes are becoming more efficient and accurate.

One notable development is the speed of metal 3D printing. Machines now produce intricate designs in less time than ever. However, there are still challenges. Some methods struggle with consistency, leading to flaws in the final product. This inconsistency raises concerns among engineers and manufacturers.

Moreover, the environmental impact of metal printing requires attention. Recycling metal powder is essential, yet not widely practiced. Many companies still dispose of waste material, which is not ideal. Finding better solutions for this waste is crucial as the industry grows. Innovations need to address these shortcomings as we embrace the future of metal printing.

Metal printing technology is transforming various industries in 2026. It enables the creation of complex structures. This process minimizes waste, which is crucial in production. Industries like aerospace benefit significantly from the lightweight components produced through metal printing. These components offer strength without adding excess weight, making them ideal for aircraft.

In the automotive sector, metal printing facilitates rapid prototyping and customization. Manufacturers can produce parts tailored to specific needs. This flexibility can lead to more efficient designs but may also introduce challenges. Not every design translates well into printed form. Attention to detail in the design process is essential.

Medical applications also see positive impacts. Customized implants and surgical tools tailored to individual patients improve outcomes. However, the speed of advancement raises questions. Are medical professionals prepared for these changes? There is a need for ongoing education and training within the medical community. Adaptation is not always seamless, and challenges will continue to emerge as the technology evolves.

Metal printing technology is transforming the manufacturing landscape in profound ways. In 2026, we see applications extending beyond traditional industries. Aerospace companies are using it to create lightweight components. This significantly reduces fuel consumption and costs. Medical device manufacturers also benefit, producing customized implants tailored to individual patients.

However, challenges persist. The quality of printed parts can vary. This inconsistency questions reliability in critical applications. Engineers must refine their processes. Testing protocols are essential to ensure safety and performance. Additionally, material waste during printing remains an issue. Designers need to rethink strategies to minimize waste while ensuring product integrity. The evolution of metal printing demands ongoing innovation and critical analysis.

Metal printing technology is rapidly evolving, delivering sustainable solutions for various industries. In a recent report, the global metal 3D printing market is projected to reach $10.7 billion by 2026. This growth highlights the increasing adoption of metal printing as a cost-effective alternative to traditional manufacturing methods.

One key benefit is reduced material waste. Traditional machining processes can generate up to 90% waste. In contrast, metal printing uses only the required amount of material, significantly lowering costs and environmental impact. According to industry data, companies can cut production costs by up to 30% using metal printing techniques. Yet, challenges remain. The technology's initial setup costs can be high, and not all metal printing methods are suitable for every application.

Furthermore, sustainability is becoming a core focus. The ability to recycle metal powders used in printing can minimize environmental footprints. Data shows that up to 50% of metal powder can be reused in subsequent prints. However, questions about the long-term durability of printed parts still linger. While metal printed components can perform well, their reliability needs continuous evaluation as the industry matures. Understanding these nuances is vital for companies looking to implement metal printing solutions effectively.

| Application Area | Material Type | Sustainability Index | Cost-Effectiveness (per unit) |

|---|---|---|---|

| Aerospace Components | Titanium Alloy | High | $150 |

| Medical Implants | Cobalt-Chromium Alloy | Medium | $200 |

| Automotive Parts | Aluminum Alloy | High | $75 |

| Industrial Tooling | Tool Steel | Low | $100 |

| Consumer Electronics | Stainless Steel | Medium | $50 |

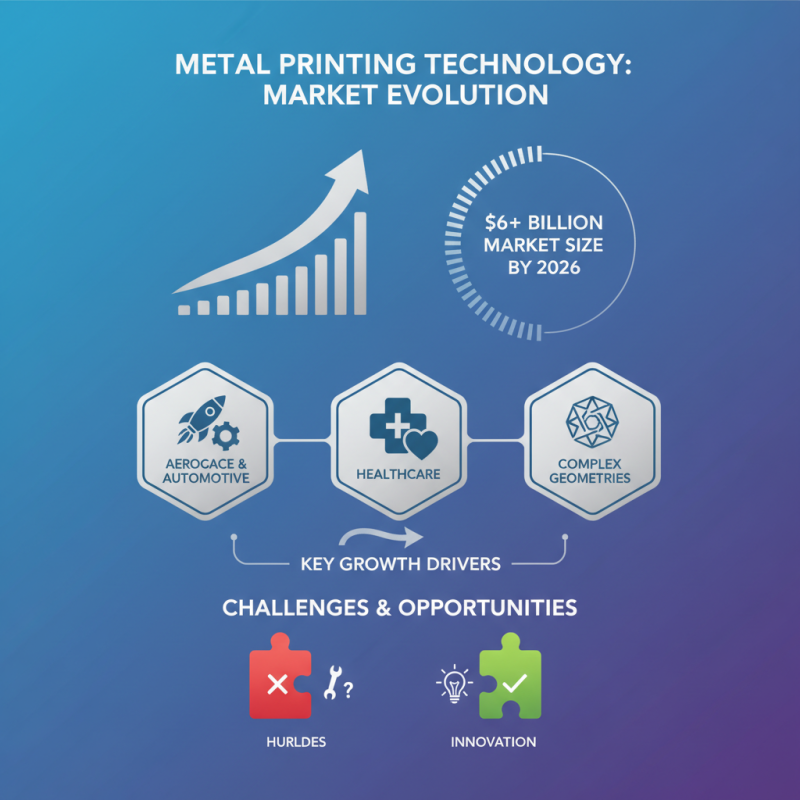

The field of metal printing technology is evolving rapidly. By 2026, it is predicted to reach a market size of over $6 billion. This growth is driven by its adoption in aerospace, automotive, and healthcare industries. Companies are increasingly attracted to its ability to produce complex geometries. However, challenges still remain.

A major issue is the need for standardized materials. Without uniformity, designers face significant hurdles in ensuring product reliability. According to a recent industry report, nearly 30% of manufacturers cite material inconsistency as a top concern. Moreover, speed and cost-effectiveness in production continue to be problematic. While metal printing allows for customization, it often takes longer than traditional methods.

Regulatory frameworks also pose challenges. Many firms struggle with navigating compliance issues. The technology outpaces regulatory updates, which creates uncertainty. Stakeholders must collaborate to address these hurdles. It's vital for the industry to focus on these shortcomings to fully harness the potential of metal printing. Advances are promising, but they require collective effort to refine and standardize practices.

© Copyrights Levil Technology Corp 2022