Precision CNC technology is a game changer in modern manufacturing. It allows for the creation of parts with incredible accuracy. This accuracy is critical for industries like aerospace, automotive, and medical. With precision CNC, manufacturers can produce complex shapes that meet tight tolerances. This level of detail was nearly impossible with traditional methods.

However, embracing precision CNC also presents challenges. The initial investment for advanced CNC machines can be significant. Additionally, skilled operators are essential. Without proper training, the potential of precision CNC cannot be fully realized. Mistakes in programming can lead to costly errors.

Yet, the benefits often outweigh the drawbacks. Quality control and consistency are greatly improved. This leads to reduced waste and increased efficiency. In a world where competition is fierce, precision CNC is not just important; it is essential for staying relevant in the market. Manufacturers must navigate the complexities to harness its full potential.

Precision CNC machining plays a crucial role in modern manufacturing. It allows for the creation of complex parts with tight tolerances. This technology ensures high accuracy, which is essential in industries like aerospace and automotive. Each component can fit perfectly, reducing assembly issues.

Tips: Always verify the specifications before starting a CNC project. Small mistakes can lead to significant problems later.

Precision machining reduces waste. Efficient material use is vital for sustainability. However, it's important to regularly inspect the equipment. Wear and tear can affect precision. Taking the time to maintain machines can save costs and improve quality.

Embracing precision CNC machining can enhance production speed. Yet, over-reliance on technology may also lead to skills gaps. Workers should continue developing their craftsmanship. Balancing technology with skilled labor is necessary for success.

This chart illustrates the various factors that contribute to the importance of precision CNC machining in modern manufacturing. Each factor is rated on a scale from 1 to 10, highlighting their significance in overall manufacturing processes.

Precision CNC machining plays a vital role in modern manufacturing. It offers several advantages that significantly improve production quality and efficiency. One key benefit is the ability to produce intricate designs with high accuracy. This technology reduces the margin of error, leading to better end products.

Another advantage is speed. Precision CNC machines can operate continuously with minimal downtime. They can quickly adapt to different tasks, which is crucial in today’s fast-paced market. However, there are challenges. Setting up CNC machinery can be time-consuming. Operators must have the right training to avoid mistakes.

Additionally, precision machining enhances consistency. Each component manufactured can meet strict specifications. This quality control is essential for industries like aerospace and automotive. Yet, even with precision, there's always a risk of defects. Regular maintenance and calibration of machinery are necessary. Neglecting these could lead to serious issues in production.

Precision CNC machining is crucial for modern manufacturing. It ensures that products are made with exact specifications. This accuracy significantly enhances product quality and consistency. Parts produced by CNC machines exhibit fewer defects. They fit together seamlessly, resulting in better overall performance.

However, the journey to precision is not always perfect. Operators must regularly maintain and calibrate machines. Small errors can cascade into larger issues. Training staff on best practices is essential. A skilled operator can spot anomalies before they become problems.

**Tip:** Invest in regular training sessions. Keep your team updated on the latest techniques and technologies.

Adopting strict quality control measures is vital. Conduct frequent inspections throughout the production process. This helps catch deviations early. It is also important to document these findings. Such records can reveal patterns over time.

**Tip:** Use checklists to streamline inspections. Consistency in checks leads to reliability.

Precision CNC machining plays a crucial role in modern manufacturing, particularly in enhancing cost efficiency and improving material utilization. According to industry data, precision machining can reduce waste by up to 30%. This is significant for companies looking to optimize their production processes and minimize costs. Effective use of materials can lead to not only lower expenses but also a smaller environmental footprint.

One noteworthy aspect is how precision CNC allows for tighter tolerances. Parts produced with dimensional accuracy can often be assembled more efficiently, requiring less rework. This efficiency leads to reduced labor costs. Yet, not every manufacturer adopts these technologies effectively. Some might overlook the initial investment in CNC machines, leading them to miss out on potential savings in the long run.

Tips to improve material utilization:

While the benefits are clear, not all manufacturers fully embrace precision CNC. This poses a need for continual reflection and adaptation. In a competitive landscape, those who do not evolve may fall behind. Embracing precision CNC is essential for staying relevant.

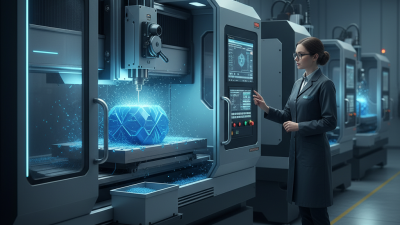

Precision CNC technology is at the forefront of modern manufacturing. It offers accuracy that traditional methods simply cannot match. This accuracy is crucial for industries like aerospace and medical devices. However, CNC machines are evolving rapidly. Innovations are emerging that could redefine production processes.

One notable trend is automation in CNC operations. Automated systems reduce human error and increase efficiency. However, this shift raises questions about job displacement. Another area of innovation is software integration. Advanced programming allows for more complex designs. Yet, mastering these new tools can be a hurdle for some operators.

These changes create exciting possibilities but also complications. As precision increases, so do production costs. Balancing quality and affordability remains a challenge for manufacturers. Exploring the potential of precision CNC is essential. But, understanding the implications of these advancements is equally vital. The future of precision CNC holds much promise, but it requires careful navigation.

© Copyrights Levil Technology Corp 2022