In the ever-evolving landscape of manufacturing, efficiency and precision are paramount. One of the most effective ways to enhance productivity in machining operations is through the utilization of advanced CNC machining centers. These cutting-edge tools not only streamline the production process but also embody the fusion of innovation and sophistication, making them indispensable in modern manufacturing environments. CNC machining centers are designed to automate complex machining tasks, significantly reducing the time and labor traditionally required for such operations.

As industries strive to remain competitive, investing in state-of-the-art CNC machining centers can lead to improved quality, faster turnaround times, and enhanced overall operational efficiency. By integrating these centers into their workflow, manufacturers can achieve higher accuracy levels and take advantage of multi-tasking capabilities that further optimize production processes. In the following sections, we will explore some of the top CNC machining centers available in the market today, focusing on their features, benefits, and how they can revolutionize manufacturing efficiency for businesses across various sectors. Whether you are a small workshop or a large-scale production facility, understanding the impact of CNC machining centers is crucial for driving success in today's dynamic manufacturing landscape.

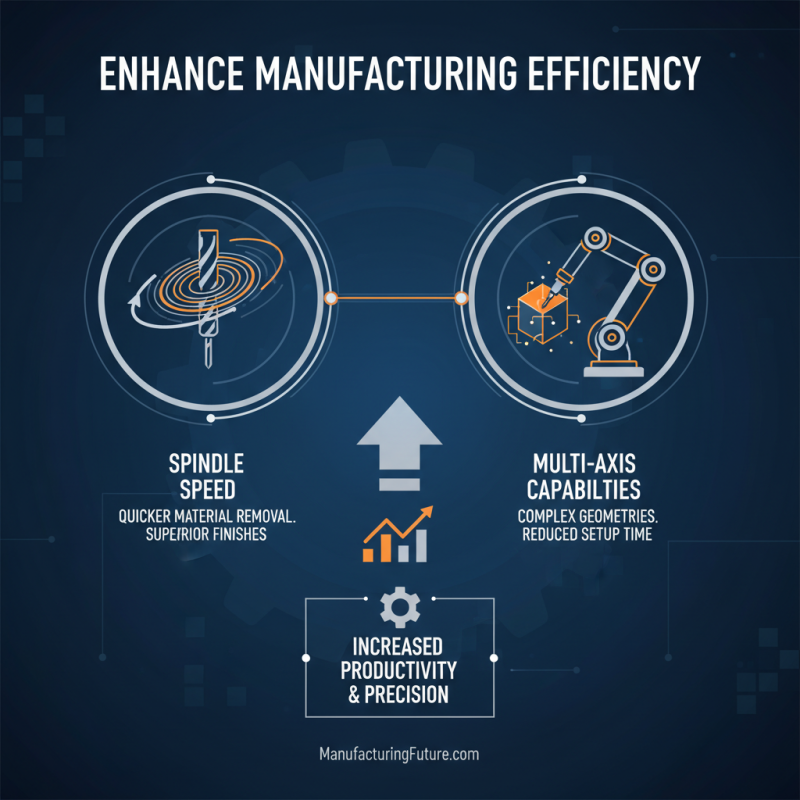

When considering high-performance CNC machining centers to enhance manufacturing efficiency, it's essential to focus on several key features that can significantly impact productivity and precision. One notable feature is the spindle speed, which dictates how quickly the machine can complete tasks. A higher spindle speed allows for quicker material removal rates and improved surface finishes, leading to increased operational throughput. Additionally, features like multi-axis capabilities enable complex geometries to be machined in one setup, reducing the need for multiple machine operations and the potential for errors during part handling.

Another critical aspect is automation integration. CNC machining centers equipped with advanced automation systems can streamline production workflows by reducing manual intervention. This feature not only minimizes cycle times but also enhances consistency and reduces the likelihood of human error. Furthermore, the implementation of real-time monitoring systems can provide valuable insights into machine performance, allowing manufacturers to anticipate maintenance needs and optimize their operation schedules effectively.

**Tips:** When selecting a CNC machining center, prioritize models that offer scalability to accommodate evolving production demands. Frequent software updates and ease of programming are also vital for maintaining competitiveness in a fast-paced manufacturing environment. Lastly, consider training for your operators to maximize the utilization of advanced features, ensuring that your investment translates into increased efficiency on the shop floor.

CNC machining centers are pivotal in modern manufacturing, providing precision, efficiency, and versatility. There are several types of CNC machining centers, each tailored for specific applications. Among the most common are vertical machining centers (VMC) and horizontal machining centers (HMC). VMCs are particularly well-suited for jobs like drilling, milling, and complex part machining, making them popular in industries such as aerospace and automotive. HMCs, on the other hand, excel in high-volume production due to their ability to quickly change tools and position parts, which significantly reduces cycle times.

In addition to these, five-axis machining centers have gained popularity due to their ability to work on complex geometries and undercuts in a single setup. These machines are invaluable in industries where intricate designs are a necessity, such as in medical device manufacturing or advanced engineering sectors. Understanding the unique capabilities of each type can help manufacturers select the best option for their production needs.

Tips: When selecting a CNC machining center, consider the specific materials you will be working with, as some centers perform better with certain materials than others. Additionally, assess the expected production volume; investing in a more advanced machine may be beneficial for high-volume tasks but could be an unnecessary expense for smaller runs. Always keep in mind the importance of proper training and maintenance to maximize the efficiency and lifespan of your CNC equipment.

CNC machining efficiency is crucial for manufacturers aiming to optimize production processes and reduce operational costs. Several factors play a significant role in determining how effectively a CNC machining center can operate. Key among these are the quality of materials, the skills of the operators, and the maintenance of the machines themselves. High-quality raw materials can enhance the machining process, leading to better finishes and reduced wear on the tools, while skilled operators are essential for setting up and managing the machinery efficiently.

Tips: Regular training sessions for operators can significantly improve their understanding of machine capabilities, enabling them to maximize productivity. Furthermore, establishing a routine maintenance schedule is vital. This not only prolongs the life of the equipment but also minimizes downtime, ensuring a smoother workflow.

Another important factor to consider is the software used to program CNC machines. Advanced software can optimize tool paths and machining strategies, leading to more efficient operations. Additionally, the integration of automation into CNC machining can allow for increased output by reducing manual handling and streamlining processing times.

Tips: Investing in the latest software updates can provide access to new features that improve efficiency. Consider conducting regular assessments of machining processes to identify potential areas for software or procedural enhancements.

In the realm of CNC machining, innovative technologies play a crucial role in enhancing manufacturing efficiency. Advanced CNC machining centers are now equipped with features such as real-time monitoring, adaptive feedback systems, and integrated software solutions that streamline production processes. By utilizing these smart technologies, manufacturers can significantly reduce downtime, optimize tool paths, and improve overall precision in machining operations.

Tips: When considering modern CNC machining technologies, invest in systems that offer remote monitoring capabilities. This allows for proactive maintenance and troubleshooting, ensuring that operations run smoothly and minimizing costly interruptions.

Moreover, the incorporation of artificial intelligence and machine learning algorithms has transformed traditional CNC machining into a data-driven process. These technologies can analyze performance metrics and predict potential issues before they arise, enabling manufacturers to proactively address them. The integration of automation further supports flexibility in production, allowing businesses to efficiently respond to changing market demands and customize orders without sacrificing speed.

Tips: Implementing automation can greatly improve workflow efficiency. Start by assessing repetitive tasks that can be automated, freeing up skilled operators to focus on more complex and value-adding activities.

| Model | Machine Type | Work Envelope (mm) | Max Speed (rpm) | Control System | Features |

|---|---|---|---|---|---|

| CNC-500 | Vertical Machining Center | 600 x 400 x 500 | 12000 | Fanuc | High Precision, Fast Tool Change |

| CNC-750 | Horizontal Machining Center | 800 x 600 x 600 | 15000 | Siemens | Multi-Axis Capable, Automated Tool Management |

| CNC-900 | 5-Axis Machining Center | 500 x 500 x 500 | 10000 | Mazak | High Flexibility, Complex Part Machining |

| CNC-1200 | CNC Lathe | 600 x 1500 | 3000 | Haas | Live Tooling, Great for Deburring |

Regular maintenance of CNC machining centers is essential to ensure optimal performance and longevity. One crucial aspect of this maintenance is keeping the machine clean and free from debris. Chips, coolant, and other residues can accumulate over time, leading to potential malfunctions and decreased precision. Implementing a routine cleaning schedule, including inspecting the bed and tool holders, will significantly reduce wear and tear, allowing for more accurate machining and prolonged equipment life.

In addition to cleanliness, regular inspection of key components, such as the spindle and linear guides, is vital for maintaining performance. Check for signs of wear, misalignment, or unusual noises during operation. Addressing minor issues promptly can prevent costly breakdowns and downtime in production. Furthermore, ensuring proper lubrication of moving parts minimizes friction and heat generation, contributing to smoother operation and enhancing the overall efficiency of the CNC machining process. Keeping a close eye on maintenance schedules and following manufacturer guidelines will lead to a significant boost in manufacturing productivity.

This bar chart illustrates the efficiency percentages of various CNC machining centers, showcasing their performance in a manufacturing environment. Understanding these metrics helps in selecting the right CNC machining center for optimal manufacturing efficiency.

© Copyrights Levil Technology Corp 2022