In the fast-evolving landscape of precision manufacturing, the role of industrial CNC machines has become more critical than ever. As experts and manufacturers alike strive to enhance productivity and accuracy, selecting the right CNC machine can make all the difference. Renowned industrial technology expert Dr. Emily Hartman noted, "Precision is not just a goal; it is a necessity in today's competitive manufacturing environment." Her insights underscore the importance of investing in advanced industrial CNC machines that not only meet but exceed the demanding standards of modern production.

As we delve into the top 10 industrial CNC machines for precision manufacturing in 2023, it’s essential to understand the advancements in technology that are shaping this industry. These machines are not merely tools; they are integral components that can significantly influence a firm's production efficiency and finished product quality. From improved control mechanisms to enhanced automation features, the latest models are designed to cater to the increasingly complex needs of various manufacturing sectors.

In this introduction, we will explore the criteria that define the most effective industrial CNC machines and highlight some of the standout options available today. By prioritizing precision, versatility, and technological innovation, manufacturers can ensure they remain at the forefront of their respective industries.

In 2023, the landscape of CNC (Computer Numerical Control) machines continues to evolve, with several types standing out for their precision in manufacturing. Among the most prominent types are CNC milling machines, CNC lathes, and CNC plasma cutters. According to a recent report by Mordor Intelligence, the CNC machining market is projected to grow at a compound annual growth rate (CAGR) of 7.9% from 2021 to 2026, underscoring the burgeoning demand for precision manufacturing that these machines facilitate.

CNC milling machines, which are vital for creating complex parts with high accuracy, are expected to see significant usage. They allow manufacturers to achieve tight tolerances and intricate designs, making them ideal for industries such as aerospace and automotive. Furthermore, CNC lathes are increasingly utilized for their efficiency in mass production of cylindrical parts. Based on data from a 2022 Statista survey, over 40% of manufacturers reported utilizing CNC lathes, highlighting their operational importance in precision tasks.

In addition to these, CNC plasma cutters are gaining traction in fabricating sheet metal with speed and precision. The ability to cut various materials with minimal distortion further enhances their appeal. As reported by Research and Markets, the global plasma cutting equipment market is expected to reach approximately $4 billion by 2026, reflecting an upward trend in the adoption of this technology in manufacturing processes. Thus, the types of CNC machines best suited for precision manufacturing in 2023 are pivotal in shaping the future of the industry.

In 2023, precision manufacturing relies heavily on advanced CNC machines that possess key features designed to enhance accuracy and efficiency in industrial applications. High-precision CNC machines incorporate advanced control systems that enable fine-tuning of machining parameters, ensuring every cut and shape meets stringent specifications. Additionally, features such as real-time monitoring and adaptive machining capabilities allow for adjustments during the process, significantly reducing waste and improving overall production quality.

When selecting a CNC machine for precision manufacturing, it’s essential to consider the machine's rigidity and stability. A stable framework minimizes vibrations, which can compromise precision during machining processes. Also, look for machines with high-resolution feedback systems to ensure accurate positioning and movement. Using the right tooling and maintaining consistent maintenance schedules can dramatically prolong machine life and uphold manufacturing standards.

Tips: Always calibrate your CNC machine before initiating a new project to ensure optimal accuracy. Incorporating a robust quality control system can help identify deviations early in the production cycle, saving both time and resources. Additionally, staying updated with software advancements can further refine your machining processes, leading to enhanced output quality.

The CNC machinery market is witnessing significant growth driven by advancements in technology and increasing demand for precision manufacturing across various industries. As manufacturers seek to enhance their production capabilities, the integration of smart technology and automation into CNC machines has become a prominent trend. This evolution not only improves operational efficiency but also reduces waste, leading to more sustainable manufacturing processes. The rise of Industry 4.0 principles has further propelled the adoption of CNC technology, allowing for real-time data analysis and machine-to-machine communication, which optimizes overall manufacturing processes.

Additionally, customization in manufacturing is gaining traction, prompting CNC machine producers to innovate and offer more flexible solutions. As industries like aerospace, automotive, and medical devices focus on high-precision components, the need for reliable and adaptable CNC machines has surged. The ability to produce small batch sizes with exceptional accuracy positions CNC machinery as an essential tool for meeting specific engineering requirements. Furthermore, the growing emphasis on sophisticated design and the reduction of lead times are reshaping the market, pushing manufacturers to invest in advanced CNC technologies to stay competitive and responsive to customer demands.

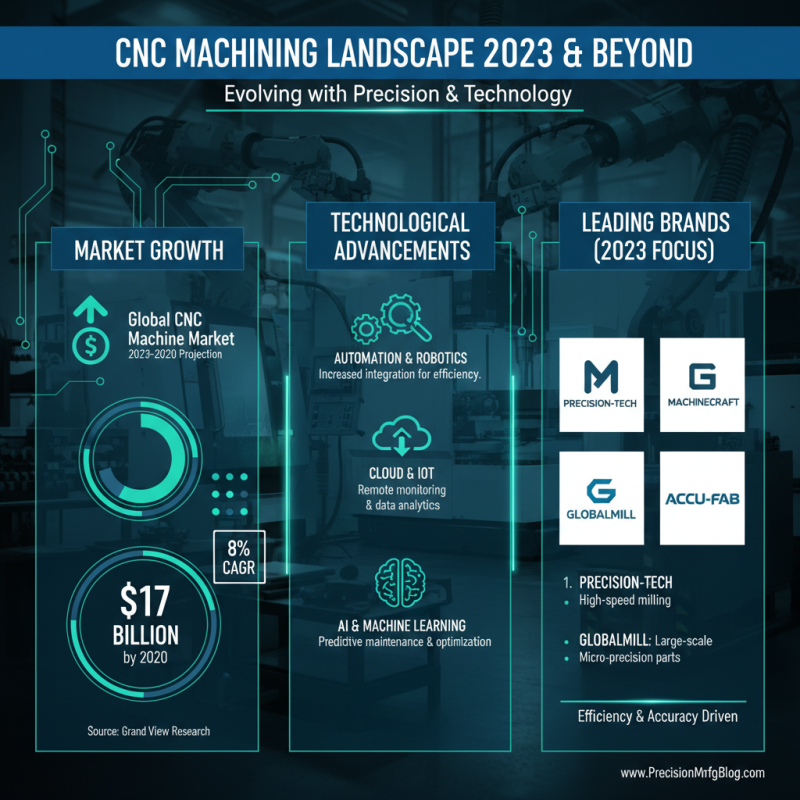

This chart illustrates the market growth and trends of the top 10 industrial CNC machines used in precision manufacturing as of 2023. The data represents the estimated market share percentage of each machine type based on various factors such as performance, versatility, and user preference.

In 2023, the landscape of CNC machining continues to evolve, driven by advancements in technology and an increasing demand for precision manufacturing across various industries. According to a recent report by Grand View Research, the global CNC machine market is projected to reach $117 billion by 2030, exhibiting a CAGR of approximately 8% from 2023. This growth underscores the importance of evaluating leading CNC machine brands that promise efficiency and accuracy in production.

When comparing top CNC machine brands, it is crucial to analyze factors such as precision capability, speed, user-friendliness, and maintenance requirements. A study published by Technavio indicates that machines with enhanced automation features are gaining traction, as they significantly reduce cycle times and improve overall operational efficiency. Precision, measured in microns, remains a critical metric, with many manufacturers seeking machines that maintain tolerances within ±0.01 mm to meet stringent industry standards. Furthermore, the integration of advanced software solutions, such as computer-aided manufacturing (CAM) systems, has revolutionized the ability for operators to optimize machining processes, leading to improved output quality and reduced waste.

In addition to performance metrics, cost-effectiveness remains a primary consideration for manufacturers. A report by Mordor Intelligence highlights that the initial investment in high-quality CNC machines often yields long-term savings through lower operational costs and enhanced product quality. As companies increasingly prioritize sustainability and waste reduction, selecting CNC machines that offer energy-efficient operations can also provide competitive advantages in a market that is increasingly driven by eco-conscious consumers and regulations.

CNC technology has undeniably transformed the landscape of manufacturing, enabling significant efficiencies and substantial cost reductions. By automating complex machining processes, industries can achieve high levels of precision with minimal human intervention. This not only enhances productivity but also reduces the likelihood of errors that can arise from manual operations. As a result, enterprises can optimize their workflows, allowing for faster prototyping and a quicker turnaround for production cycles.

Moreover, the integration of CNC machines into manufacturing processes leads to enhanced resource management. With precise control over material usage and reduced scrap rates, companies can significantly lower their material costs. The ability to produce intricate designs with high repeatability means that even small production runs can be economically viable. This agility allows manufacturers to respond swiftly to market demand, ultimately providing a competitive edge in a landscape that increasingly values speed and customization. The impact of CNC technology, therefore, goes beyond mere machinery; it redefines the strategies by which manufacturers operate, innovate, and deliver value to their customers.

© Copyrights Levil Technology Corp 2022