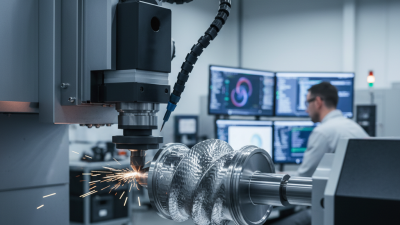

The CNC industry is experiencing a remarkable transformation. Innovations are reshaping how manufacturers operate. Advanced technologies enhance productivity, precision, and efficiency across various sectors.

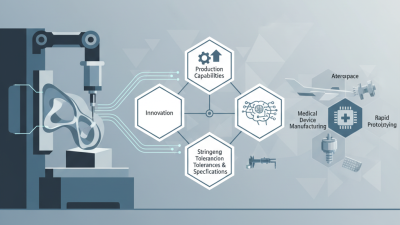

New software and tools are simplifying complex tasks. Robotics, AI, and IoT integration allow for smarter solutions. These advancements help streamline workflows and reduce errors. However, not every innovation proves effective for all companies. Some struggle to adapt to these swift changes.

The CNC landscape is evolving quickly. Companies must invest in training and upgrading equipment. Balancing innovation with traditional practices is often a challenge. While the future looks bright, the path is not without obstacles. It’s crucial to reflect on which technologies best align with individual business needs.

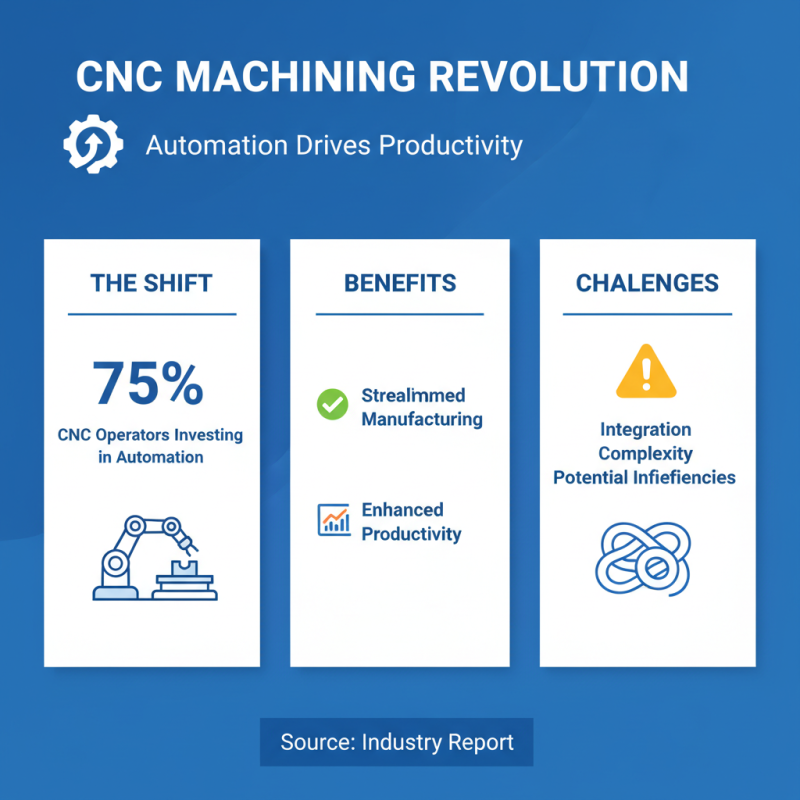

The CNC machining industry is witnessing a revolution driven by emerging automation technologies. According to a recent report, around 75% of CNC operators are investing in automation tools to enhance productivity. These tools can streamline the manufacturing process, but their implementation poses challenges. Many operators struggle with proper integration, leading to inefficiencies.

Robotics and AI algorithms are transforming CNC workflows. Automated systems reduce the need for manual labor, but not every shop can afford these technologies. Data from industry analysts indicates that while automation may cut operational costs by up to 30%, the initial investment can be daunting, limiting access for smaller firms. Many still rely on outdated methods, which can lead to slower production rates.

IoT devices are also becoming prominent in CNC machines. They create a network that allows machines to communicate. This connectivity enables real-time monitoring of production processes. However, cybersecurity concerns arise, as these systems can be vulnerable to attacks. Balancing innovation with security is a critical area needing attention. Addressing such challenges is essential for realizing the full potential of these advancements in CNC automation.

In the world of CNC machining, advanced materials are changing the game. The rise of composite materials and smart alloys offers new possibilities. These materials are lighter and stronger, enhancing the efficiency of CNC processes. For example, titanium composites are now used in aerospace. They reduce weight while maintaining strength.

When working with these advanced materials, it’s crucial to consider tooling compatibility. Specialized tools may be needed to handle their unique properties. The right tool can drastically improve machining accuracy and reduce wear. Make sure to test different tools as some may perform better than others.

Adapting to advanced materials can be challenging. Operators might face issues with heat dissipation during machining. This is why understanding thermal behavior is essential. Fine-tuning the machining parameters can lead to better outcomes. Remember, experimenting with feed rates and speeds can lead to surprising results.

The integration of AI and machine learning in CNC operations is reshaping the industry. Machines can now analyze data in real-time. This capability allows them to predict maintenance needs and optimize performance. For instance, an AI system can detect anomalies in machining processes. It adjusts parameters on the fly to enhance efficiency.

However, challenges remain. Data collection must be accurate, and systems need proper calibration. Misalignment can lead to faulty predictions. Not all CNC operators are ready to embrace these technologies. Training is necessary to maximize potential. Some may resist change, fearing job loss. It’s important to address these concerns properly.

As AI continues to evolve, its application in CNC will deepen. The potential for improved precision and reduced waste is immense. Yet, as the industry moves forward, ensuring human oversight remains vital. Balancing automation and craftsmanship is key to success.

Additive manufacturing is changing how we view CNC applications. This technology builds objects layer by layer. It opens new possibilities for design and complexity. Traditional CNC methods often struggle with intricate geometries. But additive techniques can create shapes that were once impossible. For instance, complex internal channels can now be made easier. This reduces material waste and enhances functionality.

Despite the advantages, challenges exist. The integration of additive manufacturing with CNC processes can be complex. The workflow might need adjustments. Workers must get used to new systems. Training can be time-consuming. There’s also a risk of quality control issues. Not every product made through additive methods meets strict standards. As the industry evolves, addressing these concerns will be crucial. Embracing this frontier requires patience and creativity. Future advancements depend on how well these challenges are faced.

| Innovation | Description | Impact | Adoption Rate |

|---|---|---|---|

| Additive Manufacturing | Utilizes 3D printing for creating complex geometries. | Enhances design flexibility and reduces material waste. | 30% |

| Smart CNC Machines | Incorporate IoT technology for real-time monitoring. | Improves operational efficiency and predictive maintenance. | 25% |

| AI and Machine Learning | Used for optimizing CNC programming and operations. | Enhances accuracy and reduces lead times. | 20% |

| 5-Axis Machining | Allows for more complex shapes and precision. | Expands capabilities for intricate designs. | 15% |

| Robotics Integration | Automation of handling and part placement. | Increases production speed and consistency. | 18% |

| Virtual Reality Simulation | Used for training and design optimization. | Reduces training time and improves safety. | 10% |

| Cloud Computing in CNC | Utilizes cloud services for data management. | Facilitates collaboration and data accessibility. | 8% |

| Advanced Material Use | Use of composite and lightweight materials. | Improves performance and reduces weight. | 12% |

| Enhanced Safety Features | Incorporation of safety sensors and automation. | Reduces accidents and improves worker safety. | 14% |

The CNC industry is witnessing a paradigm shift driven by IoT and smart factory concepts. These technologies are enhancing efficiency at every stage of production. For instance, real-time data is enabling machines to communicate vital information. Operators can now monitor performance remotely. This leads to timely maintenance and minimal downtime.

However, challenges persist. Integrating IoT with existing systems is not always seamless. Many machines lack the necessary infrastructure. Data security concerns also arise with increased connectivity. Companies must address these issues to fully leverage the benefits of smart factories.

Despite imperfections, the impact of these innovations is clear. Enhanced monitoring allows for precise adjustments during machining processes. Productivity gains are noticeable. Manufacturers are producing higher-quality parts with fewer errors. Embracing these technologies can propel companies to new heights, but careful implementation is crucial.

© Copyrights Levil Technology Corp 2022